Tapes with PVC foam that are used in various industries for insulation, sealing and mounting applications are the best versatile adhesive products. This foam carrier is coated with a pressure-sensitive adhesive on one or both sides and these tapes offer exceptional conformability and cushioning properties and also composed of a closed cell polyvinyl chloride. Their ability to create a reliable seal against moisture, dust, and air infiltration is one of the primary advantages of this tape and making them ideal for weather sealing in doors, windows and automotive applications. This tape also ensures a lifelong performance in outdoor and damp environments. The closed cell structure of the foam provides excellent resistance to water absorption.

- Best to be used for the electronic enclosures

This adhesive helps to prevent heat loss or gain in HVAC systems and electronic enclosures. PVC foam tapes exhibit good thermal insulation properties. Creating a tight seal even on rough or uneven surfaces, this tape is soft and flexible in nature which allows them to conform to irregular surfaces. Providing a strong bond without the need for mechanical fasteners, these tapes are often used for mounting lightweight objects, such as trims, nameplates and signs. While offering excellent durability and aging resistance these PVC tapes are high tack adhesive which ensures quick and easy installation.

- Comes with excellent bonding

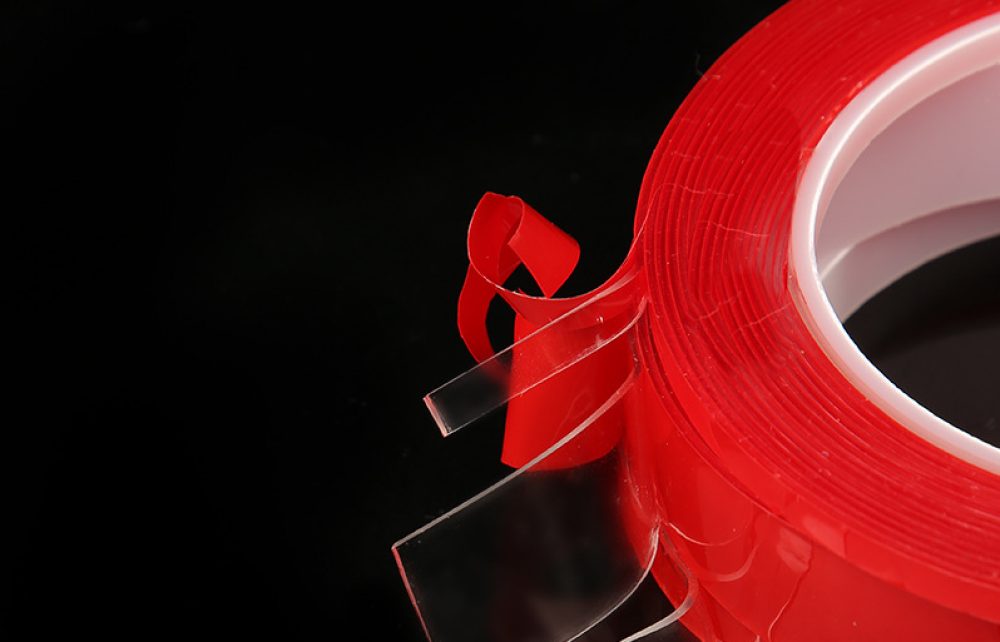

Known for their exceptional bonding strength, durability, and versatility acrylic foam tapes are considered as the most advanced products in this segment. These tapes offer unique benefits for a wide range of applications across industries and are composed of a viscoelastic acrylic foam core and coated with acrylic adhesive on both sides. Due to their superior bonding strength, weather resistance, and ability to accommodate thermal expansion differences, these tapes are indispensable in various industries. Enhancing the overall aesthetics of finished products, this translucent or tinted foam core allows for discreet bonding. These acrylic tapes are commonly used in automotive assembly, signage, and electronics manufacturing.