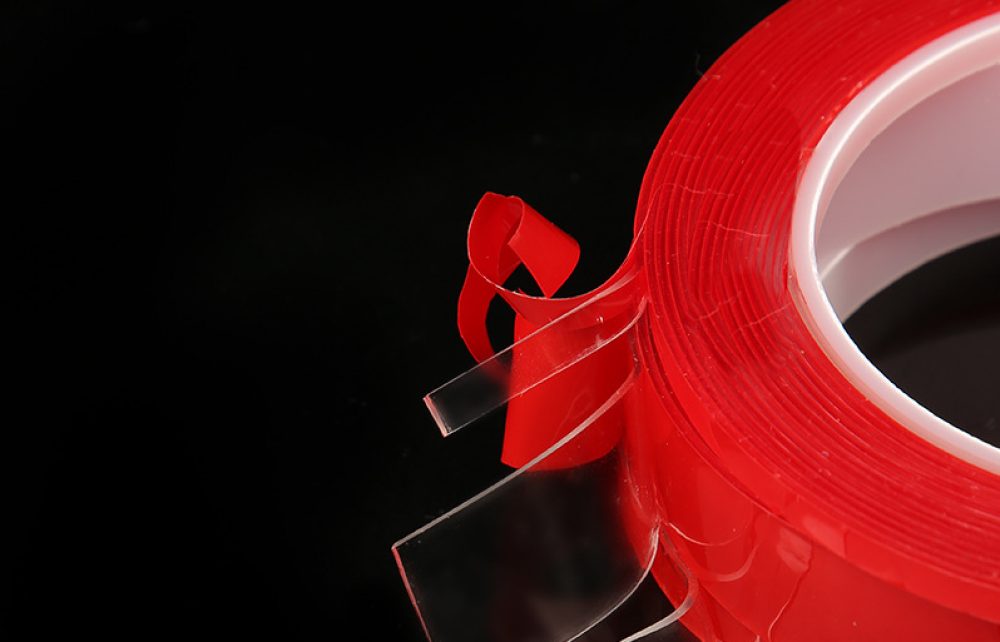

Acrylic double-sided foam tape has a wide range of uses across industries. Its flexibility is limitless, spanning car production, signs, building, and electronics. This tape clings to a wide range of surfaces, including metal, plastic, glass, and even low-surface-energy substrates, ensuring a secure bond in almost any setting.

Strength and Durability

One of the most notable characteristics of acrylic foam tapes is their extreme strength and durability. These tapes are designed to withstand severe temperatures, UV exposure, moisture, and chemical exposure, resulting in a long-lasting connection that can tolerate hard circumstances without fail. Whether used indoors or outdoors, in hot or cold weather, acrylic foam tapes maintain their integrity, giving users piece of mind.

Enhanced aesthetics

Acrylic double sided tape is not only useful but also attractive. Unlike typical fasteners like screws or rivets, this tape forms a smooth, seamless connection that improves the look of the finished product. Its capacity to transfer stress equally over the bonded surface minimizes deformation or damage while maintaining the substrate’s visual attractiveness.

Easy to apply

Another distinguishing feature of acrylic foam tapes is their simplicity of application. They eliminate the need for expensive technology or specialist skills by using a simple peel-and-stick mechanism, which speeds up the bonding process and reduces assembly time. This user-friendly characteristic makes acrylic foam tapes suitable for a wide range of industries and applications, from large-scale production to DIY projects.

Environmental friendliness

In an era where sustainability is increasingly important, acrylic double-sided foam tape stands out as an environmentally friendly alternative to traditional attaching techniques. These tapes are manufactured without solvents or volatile organic compounds (VOCs), reducing environmental impact while providing great performance. Furthermore, their endurance decreases the need for frequent replacements, resulting in less waste formation.

Acrylic double-sided foam tape is the pinnacle of adhesive innovation, combining adaptability, strength, beauty, simplicity of use, and environmental conscience in a single product. Whether gluing car trim, mounting signs, or assembling electronics, this extraordinary tape continues to push the boundaries of current bonding solutions. As industries grow and difficulties emerge, acrylic foam tapes are ready to meet tomorrow’s expectations, one bond at a time.